Birla Cellulose’s Groundbreaking Case Study: Sustainable Credentials of Recovered Sodium Sulphate from MMCF (VSF) Manufacturing

November 27, 2023Birla Cellulose, a global leader in sustainable and innovative fiber solutions, announces the release of a comprehensive case study shedding light on the sustainable credentials of recovered Sodium Sulphate (SS) from its Viscose Staple Fiber (VSF) manufacturing process.

Sodium Sulphate, a vital inorganic chemical with a wide range of applications, is obtained through either natural means, predominantly mining, or synthetically from diverse chemical industries.

As a fundamental component in numerous industrial processes, Sodium Sulphate is pivotal in various sectors, including manufacturing, pharmaceuticals, and detergents. Its versatility and widespread use make it an indispensable substance in today's global economy.

However, the extraction of natural sodium sulphate has been identified as a process that presents substantial environmental challenges, with potential consequences such as resource depletion and biodiversity loss.

Recognizing the need for sustainable alternatives, Birla Cellulose, in collaboration with BluWin Ltd., UK, undertook a pioneering case study to evaluate the eco-friendly aspects of recovered Sodium Sulphate from its VSF manufacturing. This groundbreaking initiative brought together Birla Cellulose's fiber manufacturing sites, central sustainability, chemical marketing, and branding and communication teams. External collaborations with BluWin Ltd., NimkarTek Services, and ZDHC further enriched the project with diverse expertise.

Purpose, Process, and Results

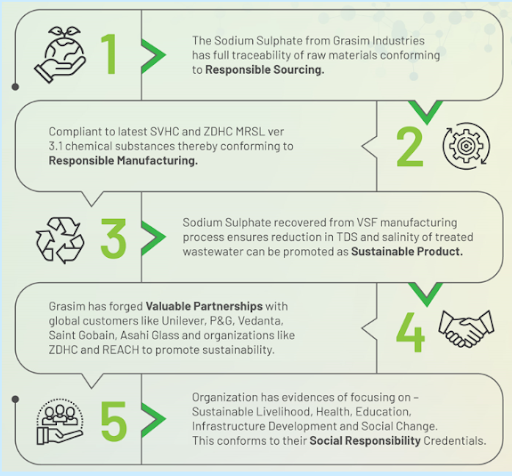

The case study's primary objective was to comprehensively assess the sustainable credentials of recovered Sodium Sulphate, focusing on circular flows in energy, water, emissions, and raw materials traceability.

The evaluation included the following aspects:

- Careful on-site testing of the Anhydrous Sodium Sulphate process

- Raw material production process

- Formula/inventory management

- Compliance/regulatory verification as per EPA, GMP &

- Occupational Safety and Health Administration

- Acceptance to REACH, ZDHC MRSL.

Here’s what we found:

Sustainable Benefits of Recovered Sodium Sulphate Through our process and evaluation, we found 3 major benefits.

- First, we set a benchmark standard by surpassing other MMCF industry players in the amount of Sodium Sulphate recovered.

- Second, the increased recovery of Sodium Sulphate plays a pivotal role in reducing the salinity of wastewater. This not only maximizes water recycling efforts but also contributes to sustainable pip practices.

- Third, higher recovery rates have facilitated the production of MMCF with the world's lowest water consumption.

This case study represents a significant milestone in their commitment to sustainability and responsible manufacturing practices. By exploring the environmental impact of recovered Sodium Sulphate, they aim to contribute to a more sustainable and eco-friendly future for the entire industry.

By prioritizing circular flows in energy, water, emissions, and raw materials traceability, Birla Cellulose is at the forefront of fostering a closed-loop system. The insights gained from this study propel us toward a future where recovered Sodium Sulphate plays a key role in sustainable and low-impact manufacturing practices. We remain dedicated to pushing the boundaries of innovation and sustainability, shaping a textile and fiber industry that values resource efficiency and environmental stewardship.

About Birla Cellulose

As a pioneer in the field of sustainable fibres, Birla Cellulose, a part of the Aditya Birla Group, sets new standards for innovation, quality, and environmental responsibility. The company is always pushing the limits of what is possible in fibre technology, developing new, cutting-edge ways to meet the changing needs of the fashion and textile industries.

The sustainable fibres offered by Birla Cellulose's extensive product line allow the company to serve various markets. Their fibres, like Viscose, Modal, and Lyocell, are known for being soft, comfortable, and easy to work with. It prioritizes environmental protection and strives to leave as little carbon imprint as possible. Birla Cellulose is steadfast in its commitment to environmental governance, which extends from the ethical procurement of raw materials to the use of environmentally beneficial methods of manufacturing.